SELECTRA

Electronics

DFM temperature control systems from Maxitrol are intended for use in direct gas-fired, DFM14 and 44 supply air heating systems. The DFM 14 and DFM 14 E systems control the exhaust air temperature. The “E” series is designed to meet the applicable ANSI Z83.18 specifications.

DFM temperature control systems from Maxitrol are intended for use in direct gas-fired, DFM14 and 44 supply air heating systems. The DFM 14 and DFM 14 E systems control the exhaust air temperature. The “E” series is designed to meet the applicable ANSI Z83.18 specifications.

DFM temperature control systems from Maxitrol are intended for use in direct gas-fired, supply air heating systems. The DFM 44 and DFM 44 E systems control the room temperature. The “E” series is designed to comply with the applicable ANSI Z83.18 specifications.

DFM temperature control systems from Maxitrol are intended for use in direct gas-fired, supply air heating systems. The DFM 44 and DFM 44 E systems control the room temperature. The “E” series is designed to comply with the applicable ANSI Z83.18 specifications.

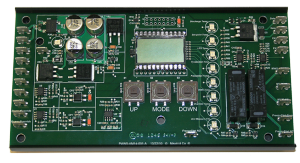

The MP2 and MP2+ systems are ideal for multiple time-dependent and temperature-critical process applications requiring temperatures from 16 °C (60 °F) to 116 °C (240 °F).

The MP2 and MP2+ systems are ideal for multiple time-dependent and temperature-critical process applications requiring temperatures from 16 °C (60 °F) to 116 °C (240 °F).

| Part number | Description |

| AM02, (AM02+ for MP2+) | Amplifier |

| TDM02 | Interface (keyboard display) |

| TM02 (optional) | Multifunctional time control |

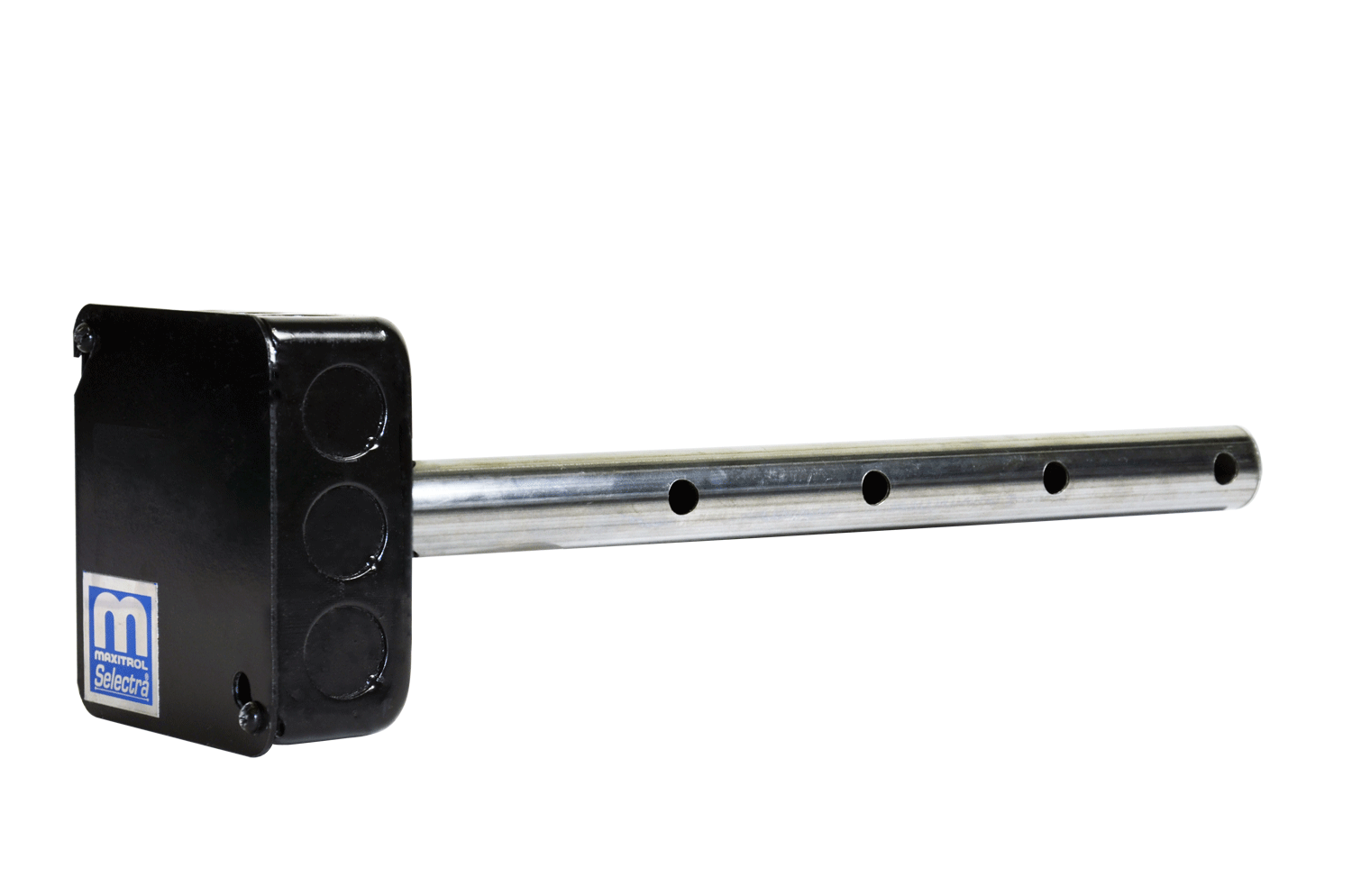

The Selectra Series 14 electronic gas modulation systems are primarily designed as components for direct-fired supply air heating systems. They can be retrofitted on site in existing systems or specified for installation in new systems.

The Selectra Series 14 electronic gas modulation systems are primarily designed as components for direct-fired supply air heating systems. They can be retrofitted on site in existing systems or specified for installation in new systems.

The Selectra Series 14+ electronic gas flame modulation systems are primarily designed as components for direct-fired supply air heating systems. The system is specified for the installation of new appliances and can be retrofitted to existing appliances in the field. (Ask the appliance manufacturer about compatibility).

The Selectra Series 14+ electronic gas flame modulation systems are primarily designed as components for direct-fired supply air heating systems. The system is specified for the installation of new appliances and can be retrofitted to existing appliances in the field. (Ask the appliance manufacturer about compatibility).

Selectra Series 24 electronic gas flame modulation systems are specifically designed for applications such as portable, direct-fired heaters. See Maxitrol Bulletin MMR_MR_MR_MT of the M/MR valve selection and application table.

Selectra Series 24 electronic gas flame modulation systems are specifically designed for applications such as portable, direct-fired heaters. See Maxitrol Bulletin MMR_MR_MR_MT of the M/MR valve selection and application table.

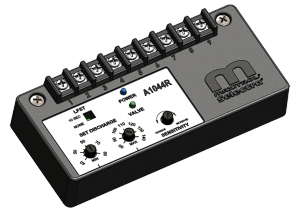

Selectra Series 44R electronic flame modulation systems are primarily designed as components for space heating systems of direct fired appliances. They can be retrofitted to existing systems in the field or specified for the installation of new systems. The Series 44R system uses modulating and modulating-regulating valves. The system is compatible with all gas types. See Maxitrol Bulletin MMR_MR_MR_MT of the M/MR valve selection and application table.

Selectra Series 44R electronic flame modulation systems are primarily designed as components for space heating systems of direct fired appliances. They can be retrofitted to existing systems in the field or specified for the installation of new systems. The Series 44R system uses modulating and modulating-regulating valves. The system is compatible with all gas types. See Maxitrol Bulletin MMR_MR_MR_MT of the M/MR valve selection and application table.

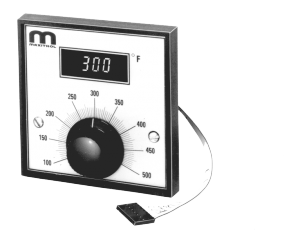

The Selectra Series 94 electronic flame modulation systems are used in commercial/industrial applications. The system can be configured for direct or indirect fired appliances. Series 94 systems utilize modulating and modulating-regulating valves. Refer to Maxitrol Bulletin MMR_MT for M/MR valve selection and application chart.

The Selectra Series 94 electronic flame modulation systems are used in commercial/industrial applications. The system can be configured for direct or indirect fired appliances. Series 94 systems utilize modulating and modulating-regulating valves. Refer to Maxitrol Bulletin MMR_MT for M/MR valve selection and application chart.

The Selectra Series 20 electronic flame modulation systems have been designed primarily for commercial and industrial space heating, as components of indirect-fired systems with atmospheric burners. The Selectra Series 20 is designed for one or more (up to four) heating furnaces. The system uses modulating and modulating-regulating valves.

The Selectra Series 20 electronic flame modulation systems have been designed primarily for commercial and industrial space heating, as components of indirect-fired systems with atmospheric burners. The Selectra Series 20 is designed for one or more (up to four) heating furnaces. The system uses modulating and modulating-regulating valves.

The Selectra Series 21 electronic gas flame modulation systems are primarily designed as components for indirect-fired supply air heating systems with atmospheric burners. Series 21 combines the capabilities of Series 21 and 31 and is designed for one or more (up to four) heaters. Series 21 systems use modulating and modulating-regulating valves.

The Selectra Series 21 electronic gas flame modulation systems are primarily designed as components for indirect-fired supply air heating systems with atmospheric burners. Series 21 combines the capabilities of Series 21 and 31 and is designed for one or more (up to four) heaters. Series 21 systems use modulating and modulating-regulating valves.

Selectra Series 92 electronic gas flame modulating systems are designed for indirect fired applications with higher single-stage turndown ratios. The Selectra Series 92 systems use modulating and modulating-regulating valves.

Selectra Series 92 electronic gas flame modulating systems are designed for indirect fired applications with higher single-stage turndown ratios. The Selectra Series 92 systems use modulating and modulating-regulating valves.

Selectra Series 94 electronic gas flame modulation systems are used in commercial/industrial applications. The systems can be configured for direct or indirect fired appliances. Selectra Series 94 systems utilize modulating and modulating-regulating valves.

Selectra Series 94 electronic gas flame modulation systems are used in commercial/industrial applications. The systems can be configured for direct or indirect fired appliances. Selectra Series 94 systems utilize modulating and modulating-regulating valves.

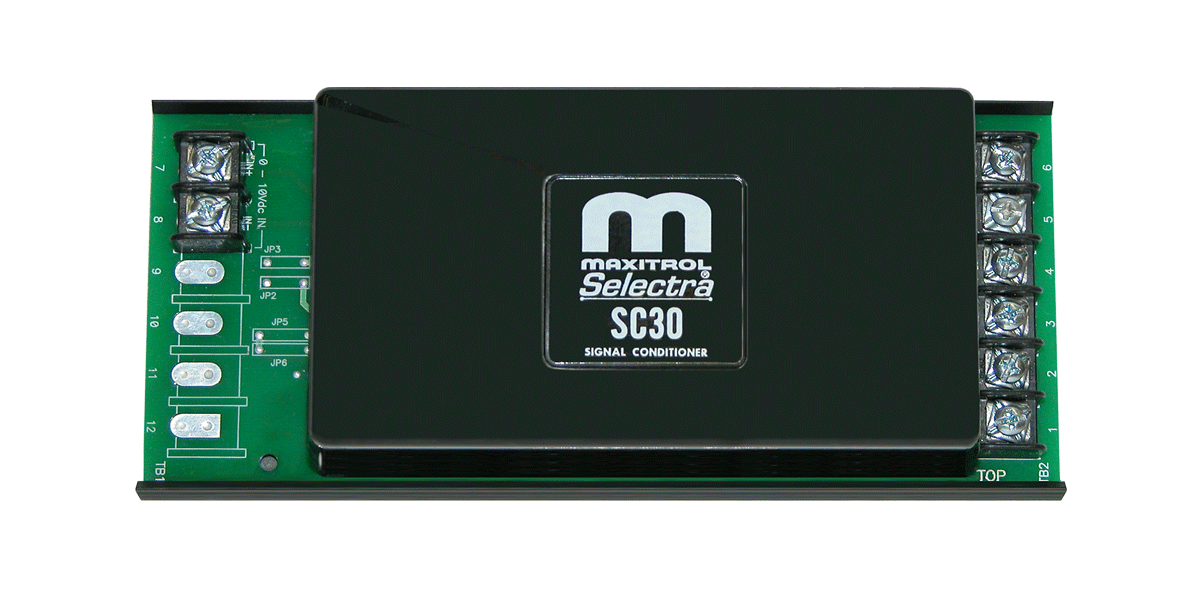

Signal conditioners

Maxitrol’s signal conditioners can be used in direct or indirect fired gas applications. They can be retrofitted into existing systems or specified for new systems.

| Model | Input (control signal) |

| SC11‑B | 4–20 mA or 0–10 VDC input (replaces SC10-A6S2, SC10-V6S2, SC10-B6S1) |

| SC11‑S | 4–20 mA or 0–10 VDC input with adjustable “Low Fire Start Timer” (low load start timer) |

| SC25S | 4–20 mA or 0–10 VDC input with min/max exhaust air temperature limit value and optional adjustable low load start timer (replaces SC20C-B6S2) |

| SC30 | 0–10 VDC input for indirect-fired gas applications with 2‑speed inductors and 2‑stage valve |

| SC30-SM2 | 0–10, 2–10 VDC or 0–20, 4–20 mA |

| SC40 | 0–10, 2–10 VDC or 0–20, 4–20 mA |

| SC40-SM2 | 0–10, 2–10 VDC or 0–20, 4–20 mA |

| D‑SC1 | 0–5, 1–5, 0–10 VDC or 1–20, 4–20 mA |

Options

| Model | Description |

| ES225 | Modified TS244 (use with TD244) |

| ES261‑1 | Split TD114 — Remote Selector (use with ES261‑2) |

| ES261‑2 | Split TD114 — Remote Selector (use with ES261‑1) |

Sensors to reset the inlet air

(Sensor only, use with mixing tube)

| Model | Description |

| TS10765A | Reset 8:1 ratio |

| TS10765B | Reset 5:1 ratio |

| TS10765C | Reset 3:5:1 ratio |

Accessories

| Model | Description |

| 101408 | Selector stop for 75° — TD114 installed |

| 101714 | Selector stop for 140° — TD114B |

| KT/94DS | Selector stop for TD92 |

| KT/294DS | Selector stop for TD294 |

| EA-14 | A1014 Housing for 4 1/2″ x 7″ |

| EA-44 | A1044 Housing for 4 1/2″ x 9″ |

| EC94-36 | 36″ Extension cable for TD94 and TD294 |

| ETD‑1 | Housing for TD114, TD120, TD121 |

| ETP‑1 | Cover, without housing for TD114, TD120, TD121 |

The Beta series electronic temperature controllers with open design are a cost-effective alternative to the use of mechanical or pneumatic thermostats or to the use of expensive, panel-mounted temperature controllers.

When used in conjunction with the LCD3000 digital display, the temperature controllers provide the convenience of a digital display of the actual process temperature. The flexible wire probes eliminate the problems of capillary tube kinking and breakage. Quick connect terminals allow for fast installation and maintenance. The Beta series controllers are suitable for applications that require accurate, repeatable temperature control over a narrow tolerance range.

The Pakstat Series I electronic thermostat is a cost-effective alternative to the use of mechanical, pneumatic thermostats or DIN temperature controllers. With the flexible wire sensor of the Pakstat Series I, problems of capillary tube kinking and breakage are avoided. The flat plug connection enables quick installation and maintenance. Pakstat Series I controllers are suitable for applications that require accurate, repeatable temperature control through a narrow deadband.

The Pakstat Series I electronic thermostat is a cost-effective alternative to the use of mechanical, pneumatic thermostats or DIN temperature controllers. With the flexible wire sensor of the Pakstat Series I, problems of capillary tube kinking and breakage are avoided. The flat plug connection enables quick installation and maintenance. Pakstat Series I controllers are suitable for applications that require accurate, repeatable temperature control through a narrow deadband.

The Pakstat Series II electronic thermostats are a cost-effective alternative to mechanical or pneumatic controllers with separate thermometers or DIN temperature controllers. When used in conjunction with the LCD3000 model digital display, it provides the convenience of a digital display of the process temperature. The LCD3000 is a 3–1/2 digit display with a resolution of 1°. The accuracy of 1% +/- one digit meets the requirements of most food storage standards. The Pakstat Series II flexible wire sensor eliminates capillary tube kinking and breakage problems. The flat plug connection enables quick installation and maintenance.

Pakstat Series II controllers are suitable for applications requiring accurate, repeatable temperature control with a narrow deadband (up to +/- 1°).

The electronic thermostats in the Trakstat series are a cost-effective alternative to the use of mechanical or pneumatic controllers. The design flexibility of the Trakstat and its economical design meet the requirements of most device manufacturers (OEMs) for a temperature controller.

The Trakstat controller can incorporate an RTD sensor or a thermistor. These types of sensors avoid capillary tube kinking problems and their calibration is independent of atmospheric pressure changes.

The Trakstat offers versatile mounting options. Setpoint options include a factory-set fixed setpoint, a latching control shaft or an external potentiometer where mounting space is limited. The U.L. and C.S.A. approved 20 amp output relay meets most load requirements and can be configured to operate a solid state relay. The flat plug connection allows for quick installation and maintenance.

| Title | Description | Version | Download |

|---|---|---|---|

| DFM Temp. Control System | Literature; For direct fired makeup air heaters. DFM14 & 14E control discharge air temperature. DFM44 & 44E control space temperature. | 🇺🇸 FL2104 01/06 | DownloadPreview |

| MP2 & MP2+ Series | Literature; Programmable process & temperature control system. | 🇺🇸 MP2_MS_EN_04.2008 | DownloadPreview |

| MP2 | Programming Guide; Programming, operation, field checklist, valve adjustment. | 🇺🇸 MP2_UG_EN_07.2007(08.2013) | DownloadPreview |

| MP2+ Temperature Controller | User/Programming Guide; for multiple temperature critical & time sensitive process applications required temperatures 60°F to 240°F. | 🇺🇸 MP2+_UG_EN_07.2007(08.2013) | DownloadPreview |

| SC11 Signal Conditioners | Installation Instructions; For direct or indirect fired applications. Drives multiple Selectra valves simultaneously. | 🇺🇸 SC11_OEM_MS_EN_11.2017 | DownloadPreview |

| SC11 & SC25S Signal Conditioner | Installation Instructions; Analog signal conditioners convert selectable 0-10 VDC or 4-20 mA control signal to an output level capable of driving one or more Selectra valves. | 🇺🇸 SC11S_25S_MS_EN_11.2017 | DownloadPreview |

| SC30 Signal Conditioner | Installation Instructions; Converts a selectable 0-10 VDC to a 0-20 VDC signal capable of driving a Selectra valve. | 🇺🇸 SC30_MS_EN_09.2012 | DownloadPreview |

| SC30-SM2 Signal Conditioner | Installation Instructions; Used with M420, M520, M620 on atmospheric indirect fired heaters w/sectioned manifold & 2-speed inducer. | 🇺🇸 SC30-SM2_MS_EN_12.2020 | DownloadPreview |

| Selectra Series 14 & 44 | Condensed Catalog; Series 14: makeup air heating, direct fired equipment. Series 44: space heating, direct fired equipment. | 🇺🇸 SEL1444_CC_EN_12.2015 | DownloadPreview |

| Selectra Series 20 & 21 | Condensed Catalog; Series 20: space heating, indirect fired units w/atmospheric burners. Series 21: makeup air heating, indirect fired units w/atmospheric burners. | 🇺🇸 SEL2021_CC_EN.08.2014 | DownloadPreview |

| Selectra Series 14 & 94 | Literature; Paint spray booth applications: Series 14 dual temp dials; w/switch; integral to amplifier. Series 94 dual dial w/LED display; "M" series microprocessor. | 🇺🇸 MS2101 (09/03) | DownloadPreview |

| TDDFM14 Thermostat | Owner's Manual; Features, wiring & mounting, programming, trouble shooting. | 🇺🇸 TDDFM14_OM_EN_11.2003 | DownloadPreview |

| TDFM44 Thermostat | Owner's Manual; Features, wiring & mounting, programming, trouble shooting. | 🇺🇸 TDFM44_OM_EN_11.2003 | DownloadPreview |